Welding processes:

CGH Polska is among a few tank manufacturers in Europe employing the approved welding technologies for austenitic (stainless) steels with fusing agent, the method 121. In addition, we use approved technologies of welding low carbon steels for application at -50oC, by following methods: fuse agent – method 121, MIG-MAG – method 135, TIG – method 141.

Our strength is offering top quality products manufactured in state of the art process:

- Automatic production line by Heinrichglück, which guarantees perfect assembly.

- Inner and outer joints shielded arc welded, using top quality welding materials.

- Cleaning of surface to Sa 2,5 cleanness grade acc. to ISO 8501-1

- Automatic application of Endopren outer insulation

- NDEs of welded joints and tightness tests of outer layer with the test voltage of 10 kV

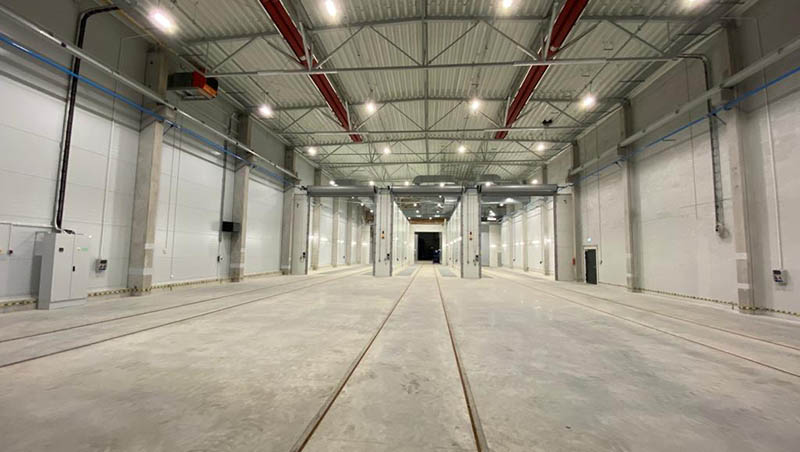

Painting hall

The biggest and most modern painting hall in Poland with 2.600m2 area, equipped with two fully automated grit blasting chambers (7,5 x 6 x 25m), PUR coating chamber (8,5 x 6 x 25m), three wet coating chambers (7,5 x 6 x 25m), final assembly area, multitonnage paint warehouse and social rooms.

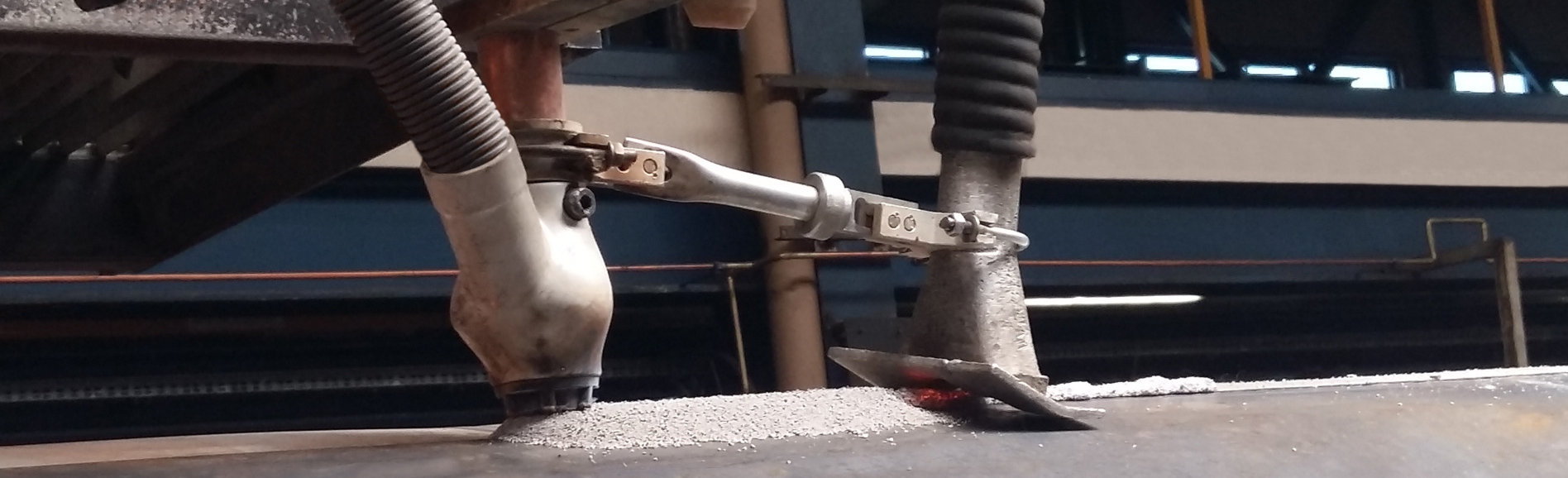

Grit blasting chamber

Two grit blasting chambers, 7,5 x 6 x 25m each, equipped with four blasting nozzles working in continues mode, sweeping floor with grit circulation and efficient ventilation providing dust extraction during blasting process.

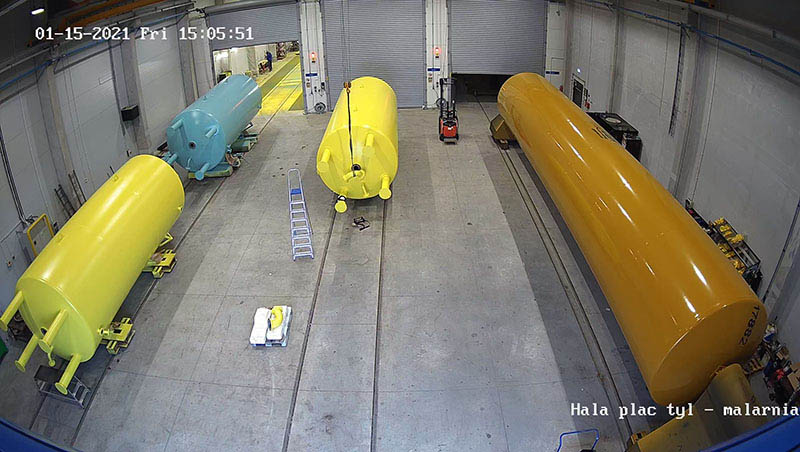

PUR coating chamber

PUR coating chamber size 8,5m x 6 x 25m supplied with tank rotators integrated with painting nozzle providing automatic paint application. The chamber has mechanical ventilation with recuperation to guarantees safety of painters and climate conditions during application.

Painting chambers

Three wet painting chambers size 7,5 x 6 x 25m each, equipped with ventilation system with recuperation, allowing to control climate conditions during paint and drying process.

Assembly area

Final assembly area for manway covers, piping and platforms, as well as for final control and leak tests on valves and pipe connections.

Robots