Advanced pipes for LPG transport

Based on more than 25 years of experience in non-metallic pipework design and project engineering in both upstream and downstream segments of the Oil & Gas Industry, CGH Belgium offers technology for safe underground LPG transport with an advanced pipe.

The flexible and continuously spooled pipes provide for an extremely rapid installation at a lower cost. The use of advanced polymers and aramid fibre braid ensures corrosion resistance, high strength and a longer lifetime. The LPG-Flex® pipes are installed in continuous runs between tank and dispenser, which eliminates all buried and inaccessible joints. The plastic inner wall is 100 times smoother than steel and smaller pipe diameters will give identical flow results as the typically larger steel pipes and flexible corrugated steel pipes.

LPG-Flex® pipes eliminate the disadvantages of traditional steel pipework, the welding with the required X-ray testing as well as the internal and external corrosion, a major concern of the safety authorities.

Applications

The LPG-Flex® pipes are used for the transport of Liquefied Petroleum Gas (LPG), propane, butane, pentane and dimethyl-ether (DME) in liquid phase as well as in gaseous phase.

Thousands of installations are in use worldwide since 2009 in many applications:

- Autogas installations in service stations of several major oils companies

- Agriculture: poultry + livestock, wheat and corn drying, frost protection

- LPG distribution centres and filling installations for gas cylinders

- Industrial applications: heating, production processes, asphalt mills…

- Heating and cooking applications in hotels in remote areas

- Firefighting training centres

- And many more…

Installation of the fittings

The NPT male thread or flanged fittings are crimped on site or in a workshop by means of a (hand operated) hydraulic radial crimping machine. The crimping action locks the pipe wall and the pipe’s braid between the insert and the ferrule, ensuring tightness and mechanical strength.

The strength of the pipe is entirely determined by the braid and NOT by the wall thickness,

making the LPG-Flex® pipe extremely flexible and easy and fast to install!

Features & composition

- Max. operating temperature:

-40 °C to +65 °C / -40 °F to 149 °F - Pipe braid design strength:

2,2 times the max. operating pressure - Max operating pressure: 35 bar – 500 psi

- Maximum testing pressure: 52 bar – 760 psi

- Min. installation temperature: 0 °C.

Pipe must be heated before uncoiling below 0 °C - Crush resistance: 25 to 30 kg/cm²/ 284 to 427 psi, depending on the pipe diameter

- Max. pulling force: 5.000 kg – 11,000 lbs

- Standard pipe diameters: DN20, DN25 and DN32, larger diameters on demand

- Disposable reels with a standard length of 200 m (659 ft) or 400 m (1318 ft)

- Pipes have length marks in meter or foot

- Only for buried applications, directly in a trench or in a secondary duct

Fittings

- Insert: carbon steel ending on male NPT thread, stub flange including slip-on flange and O-ring or 500 mm seamless carbon steel pipe. BSPT threads are available on demand

- Ferrule: 304 stainless steel

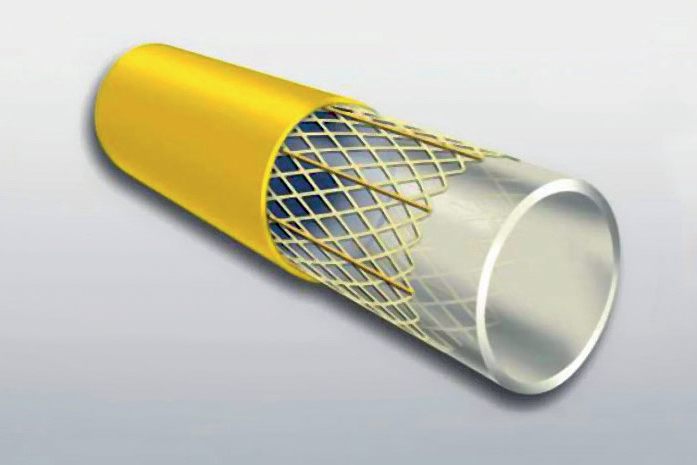

Outer jacket: Yellow polypropylene, abrasion resistant for braid protection.

Inner liner (Base tube): Nylon inner liner compatible with LPG, in both gas and liquid phase.

Reinforcement: Aramid fiber radial criss-cross braiding provides strength while the longitudinal braiding prevents elongation.

Product codes and dimensions

| Pipe | DN | O.D. mm – inch | I.D. mm – inch | Bending radius m – ft | NPT fitting | Fitting thread | Flange fitting | Tube fitting 500 mm | Tube type |

| LP1025 | 20 | 31,75 – 1 1/4″ | 22,35 – 0.88″ | 0,60 – 2 | MC20075-NPT | 3/4″ | MC20075-FLA | MC20075-500 | 22L |

| LP1050 | 25 | 38,10 – 1 1/2″ | 27,00 – 1.08″ | 0,60 – 2 | MC25100-NPT | 1″ | MC25100-FLA | MC25100-500 | 28L |

| LP1075 | 32 | 44,45 – 1 3/4″ | 33,80 – 1.33″ | 0,70 – 2.3 | MC32125-NPT | 1 1/4″ | MC32125-FLA | MC32125-500 | 35L |

Note: Coupling sleeves are AISI304, inserts are carbon steel. NPT inserts are available in AISI304.

Add -SS to the reference for stainless steel NPT inserts, e.g. MC20075-NPT-SS.

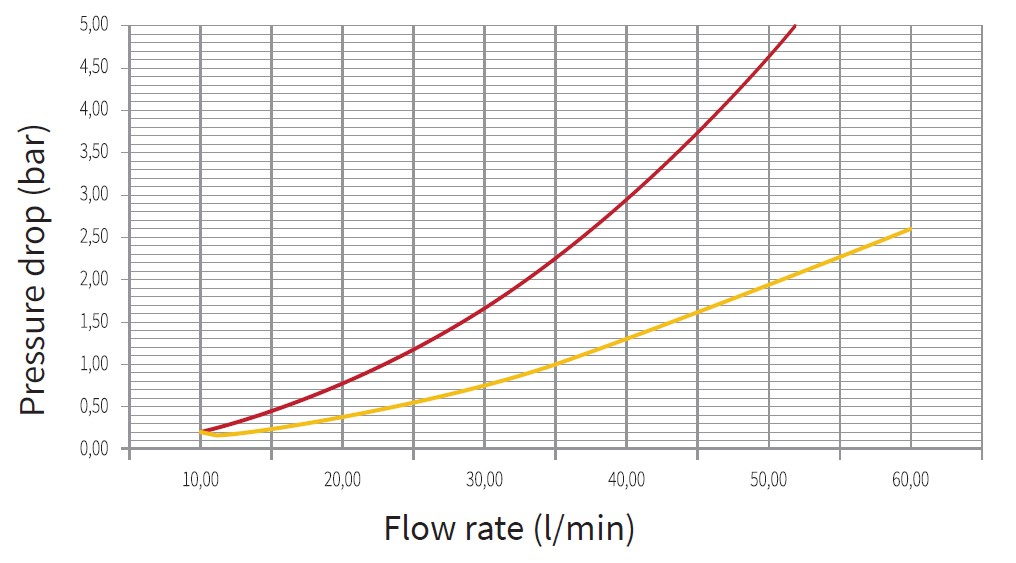

Plastics are about 100 times smoother than steel. The smaller LPG-Flex® pipes will give identical flow results than the typically larger steel pipes.

This pressure drop chart is based on a typical 80 m DN20 pipe run at different flow rates.