Polyols and isocyanates tanks are commonly used in the foam industry, particularly in the production of polyurethane foam. Polyurethane foam is a versatile material used in a wide range of applications, including insulation, furniture, automotive interiors, and more. The production process involves combining polyols (a type of alcohol) with isocyanates to create the foam.

Realization example

- Aboveground, vertical, single-skin tank made of S235 steel.

- Production according to the AD2000 norm.

- Internal anti-corrosion protection with oil ensuring the cleanliness of the medium.

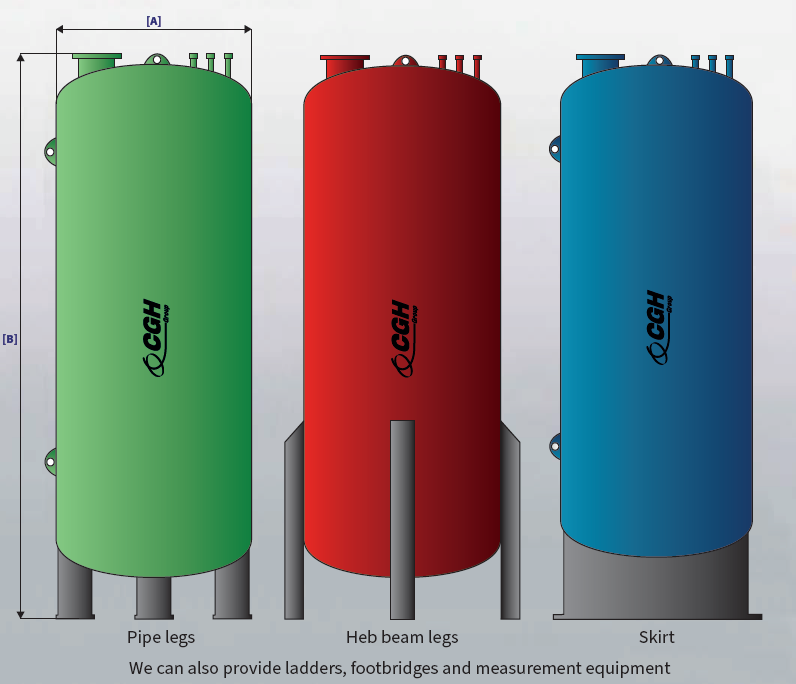

- The tanks are painted with C3M corrosivity class in various colours depending on the stored medium.

- Pressure: ambient.

- Working temperature: +10/+35°C

- Other conditions on request

Polyols and isocyanates tanks from CGH fulfill safety requirements.

We hold all necessary certificates to manufacture such tanks issued by Notified Body.

Capacities and Variants

Tanks dimensions and weights

| Tank Capacity [m³] | Tank Diameter [A] [ø] | Tank Height [B] [mm] | Tank Weight [kg] |

|---|---|---|---|

| 20 | 2000 | 8000 | 2930 |

| 20 | 2500 | 5350 | 2870 |

| 30 | 2500 | 4500 | 3810 |

| 40 | 2500 | 9700 | 4750 |

| 50 | 2900 | 9600 | 6200 |

| 60 | 2900 | 11000 | 7120 |

Other sizes up to 300m³ are available upon request.