Normobaria – the atmospheric pressure level most favourable to human health and longevity, amounting to approx. 1500 hPa.

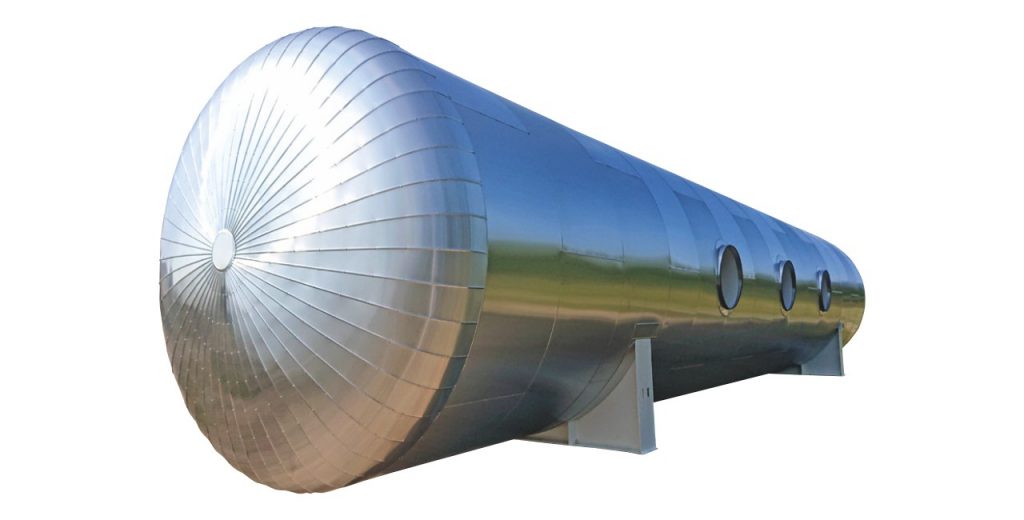

CGH Polska manufactures tanks that are used for normobaric chambers designed according to the individual needs of the Client (length, diameter, arrangement of windows and doors as well as necessary structural elements inside the tank).

The tanks bear the CE marking confirming compliance with applicable standards while maintaining high quality workmanship.

Basic technical specifications of the tank:

- Two-chamber tank consisting of the main chamber

and the lock - Tank material: carbon steel

- Diameters up to 3400 mm

- Tank total length up to 25,000 mm

- Absolute working pressure 1.5 bar

- Internal coating with the National Institute of Hygiene certificate

- External coating in corrosivity category C3M

- CE marking.

We equip the tank with automation and electrical installation together with the necessary devices for the proper operation of the chamber and for creating a normobaric environment, which, according to scientists, is an ideal environment for humans.

Control systems have been designed in accordance with applicable standards, and their implementation is based on modern solutions and high-class components by manufacturers who are well established on the market. This allows for maintaining the high efficiency of the control system used, which is also characterised by reliable operation and high flexibility ensuring its easy configuration.

Our objective is, first and foremost, the maximum safety of the users of the normobaric chamber, therefore, it is equipped with a system consisting of a certified safety module, emergency switches located in easily accessible places, whose task is to bring the interior of the normobaric chamber to the atmospheric conditions as soon as possible. The number of sensors in the normobaric chamber has been doubled to fully monitor the operating parameters, which increases safety by automatically detecting a potential failure or disruption of one of the sensors.

The visualisation of the normobaric chamber’s operation was developed on the basis of three operator screens, which are located in the central part, in the vestibule and outside. The location, type and number of operator screens can be determined individually, and the appearance of visualisation can be adapted to the needs of the Customer as well.

Main features of the control system:

- precise process flow control,

- visualisation giving a full picture of the process flow,

- editing parameter values,

- access levels: session participant, manager, device diagnostics,

- alarm system,

- reporting,

- alarm history,

- statistical features,

- charts of monitored values,

- formula system: arranging the course of a normobaric session,

- remote access via the Internet for maintenance purposes and

for remote monitoring of the chamber’s condition, - option of data exchange via Ethernet.

Monitored, regulated parameters of the normobaric chamber:

- hydrogen concentration,

- oxygen concentration,

- temperature,

- humidity,

- chamber pressure,

- carbon dioxide concentration.

In addition, there is the possibility of expansion and communication with other control systems or computer networks.

CGH manufactures tanks in various completion ranges:

- Tank with windows and doors according to the needs of the Customer

- The structure inside the tank for easy installation of devices and additional equipment

- Tank insulation with 100 mm mineral wool covered with aluminium/zinc coated or Aluminium sheet metal

- Assembly and installation of the required devices together with automation and electric installation to create a normobaric environment as well as sanitary equipment.

- Finishing with OSB floor boards (shell and core)

- The rest of the equipment, including floor panels, all furniture, small household appliances, are left to the Customer.