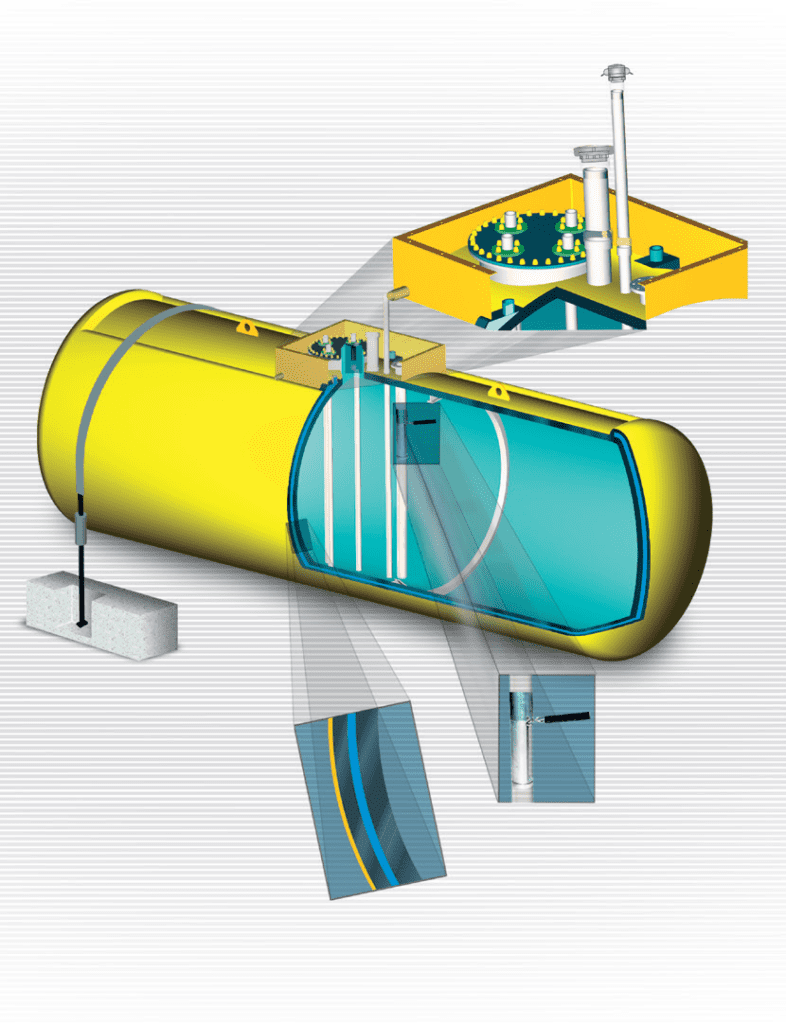

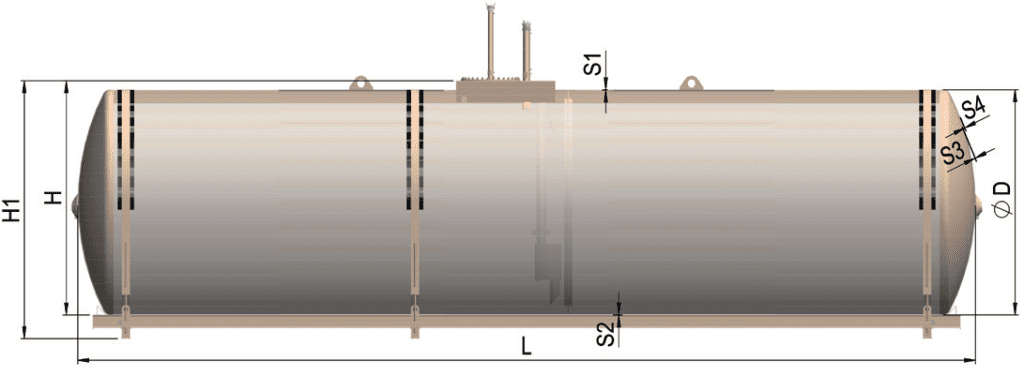

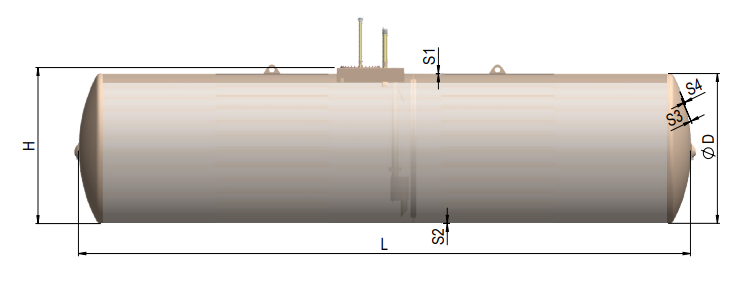

Underground double-skinned tanks

Technical data:

- Tank volumes up to 1250 m³

- Norms: EN 12285-1 Class A or Class B (underground), EN 12285-2 (aboveground), or AD 2000

- Steel grade – S235JR, optional 1.4307, 1.4404

- Single or multi-chamber tanks

- Working pressure: max 0,5 bar

- Working temperature: from -20 °C to + 50 °C

Anticorrosion protection:

- Grit-blasted to grade Sa 2,5 according to PN-ISO 8501-1

- Underground outer skin protected with min. 800μm Polyurethane coating, tested at 10 kV/14 kV

- Aboveground outer skin with corrosion protection in class C3 as standard, optional in class C4 or C5

- Optional internal anti-corrosion protection suitable for stored medium

Safety

Our tanks fufill safety requirements of various fuel storage. We hold all necessary certificates to

manufacture such tanks, issued by Notified Body approved by TÜV Nord, TDT, WDT, DIBt, SVTI.

Application

Storage of flammable and non-flammable liquids harmful to the environment with a density up to 1,1

kg/dm³ for EN 12285 Class A tanks and up to 1,9 kg/dm³ for tanks EN 12285 Class B and AD 2000.

Tightness

Factory pressure test of both the inner tank and the interstitial space according to the standard are given in the table below. For tanks with non-standard parameters,, test pressure values and test types are adapted to applicable standards and regulations.

Underground tanks according to EN 12285-1 norm, Class A & B

| Volume | Diameter | Length | Height | Height with speed chasis |

Total weight | Additional

chamber weight |

Wall thickness | Dished-end thickness | ||||||||||

| class A | class B | class A | class B | class A | class B | class A | class B | |||||||||||

| V | D | L | H | H1 | Single skin | Double skin | Single skin | Double skin | S1 | S2 | S1 | S2 | S3 | S4 | S3 | S4 | ||

| [m3] | [mm] | [mm] | [mm] | [mm] | [kg] | [kg] | [kg] | [kg] | [kg] | [kg] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] |

| 3 5 8 10 13 16 |

1600 1600 1600 1600 1600 1600 |

2260 3260 4760 5760 7260 8760 |

1770 1770 1770 1770 1770 1770 |

2030 2030 2030 2030 2030 2030 |

723 934 1250 1461 1779 2096 |

1039 1351 1817 2129 2597 3066 |

739 950 1265 1476 1794 2112 |

1055 1367 1833 2144 2613 3081 |

351 351 351 351 351 351 |

351 351 351 351 351 351 |

5 5 5 5 5 5 |

3 3 3 3 3 3 |

5 5 5 5 5 5 |

3 3 3 3 3 3 |

5 5 5 5 5 5 |

3 3 3 3 3 3 |

5 5 5 5 5 5 |

3 3 3 3 3 3 |

| 10 13 16 20 25 30 35 |

2000 2000 2000 2000 2000 2000 2000 |

3880 4880 5880 6880 8880 10380 11880 |

2170 2170 2170 2170 2170 2170 2170 |

2430 2430 2430 2430 2430 2430 2430 |

1523 1836 2150 2466 3093 3617 4088 |

2146 2586 3025 3466 4345 5057 5716 |

1538 1852 2166 2481 3108 3633 4103 |

2162 2601 3040 3482 4360 5073 5732 |

522 522 522 522 522 522 |

522 522 522 522 522 522 |

6 6 6 6 6 6 |

3 3 3 3 3 3 |

6 6 6 6 6 6 |

3 3 3 3 3 3 |

6 6 6 6 6 6 |

3 3 3 3 3 3 |

6 6 6 6 6 6 |

3 3 3 3 3 3 |

| 16 20 25 31 35 40 46 50 |

2200 2200 2200 2200 2200 2200 2200 2200 |

5010 6010 7510 9010 10510 11510 13010 14010 |

2370 2370 2370 2370 2370 2370 2370 2370 |

2630 2630 2630 2630 2630 2630 2630 2630 |

2044 2389 2907 3486 4003 4349 4926 5271 |

3398 3974 4837 5762 6625 7201 8123 8699 |

2348 2749 3350 4012 4612 5013 5673 6074 |

3703 4334 5280 6288 7234 7865 8870 9502 |

601 601 601 601 601 601 601 |

670 670 670 670 670 670 670 |

6 6 6 6 6 6 6 |

4 4 4 4 4 4 4 |

7 7 7 7 7 7 7 |

4 4 4 4 4 4 4 |

6 6 6 6 6 6 6 |

5 5 5 5 5 5 5 |

7 7 7 7 7 7 7 |

5 5 5 5 5 5 5 |

| 20 25 30 40 50 60 70 |

2500 2500 2500 2500 2500 2500 2500 |

5020 6020 7020 9020 11020 13020 15020 |

2670 2670 2670 2670 2670 2670 2670 |

2930 2930 2930 2930 2930 2930 2930 |

2366 2757 3150 4002 4788 5640 6444 |

3962 4615 5269 6645 7954 9329 10657 |

2720 3174 3630 4607 5519 6496 7426 |

4315 5031 5749 7250 8685 10186 11639 |

730 730 730 730 730 730 730 |

818 818 818 818 818 818 818 |

6 6 6 6 6 6 6 |

4 4 4 4 4 4 4 |

7 7 7 7 7 7 7 |

4 4 4 4 4 4 4 |

6 6 6 6 6 6 6 |

5 5 5 5 5 5 5 |

7 7 7 7 7 7 7 |

5 5 5 5 5 5 5 |

| 40 50 60 70 80 100 |

2900 2900 2900 2900 2900 2900 |

7130 8630 10130 11630 13130 16130 |

3070 3070 3070 3070 3070 3070 |

3330 3330 3330 3330 3330 3330 |

4286 5154 5947 6761 7631 9215 |

6831 8155 9403 10672 11998 14493 |

5407 6494 7506 8538 9626 11648 |

7952 9494 10962 12449 13993 16926 |

1045 1045 1045 1045 1045 1045 |

1279 1279 1279 1279 1279 1279 |

7 7 7 7 7 7 |

4 4 4 4 4 4 |

9 9 9 9 9 9 |

4 4 4 4 4 4 |

7 7 7 7 7 7 |

5 5 5 5 5 5 |

9 9 9 9 9 9 |

5 5 5 5 5 5 |

| 120 | 3000 | 18150 | 3170 | 3430 | 10815 | 16926 | 13640 | 19751 | 1108 | 1357 | 7 | 4 | 9 | 4 | 7 | 5 | 9 | 5 |

*Other/larger volumes available on request

S1 – Inner wall

S2 – Outer wall

S3 – Inner dished-end

S4 – Outer dished-end

Underground tanks according to AD 2000 norm

| Volume | Diameter | Length | Height | Height with speed chasis |

Total weight | Additional

chamber weight |

Wall thickness | Dished-end thickness | |||

| V | D | L | H | H1 | Single skin | Double skin | S1 | S2 | S3 | S4 | |

| [m3] | [mm] | [mm] | [mm] | [mm] | [kg] | [kg] | [kg] | [mm] | [mm] | [mm] | [mm] |

| 120 | 2900 | 18950 | 3140 | 3400 | 14543 | 20732 | 1289 | 9 | 4 | 5 | 9 |

| 120 | 3000 | 18150 | 3240 | 3500 | 13910 | 20021 | 1367 | 9 | 4 | 5 | 9 |

| 150 200 |

3200 3200 |

19750 26250 |

3440 3440 |

– – |

18041 23765 |

25110 30834 |

1671 1671 |

10 10 |

4 4 |

5 5 |

10 10 |

| 150 200 250 300 |

3400 3400 3400 3400 |

17790 23290 28790 34290 |

3640 3640 3640 3640 |

– – – – |

17681 22897 27943 33499 |

24531 31705 38710 46224 |

1862 1862 1862 1862 |

10 10 10 10 |

4 4 4 4 |

5 5 5 5 |

10 10 10 10 |

| 150 200 250 300 |

3600 3600 3600 3600 |

15870 20870 25870 30370 |

3840 3840 3840 3840 |

– – – – |

16974 22047 27121 31535 |

23527 30485 37444 43555 |

2064 2064 2064 2064 |

10 10 10 10 |

5 5 5 5 |

5 5 5 5 |

10 10 10 10 |

*Other/larger volumes available on request

S1 – Inner wall

S2 – Outer wall

S3 – Inner dished-end

S4 – Outer dished-end

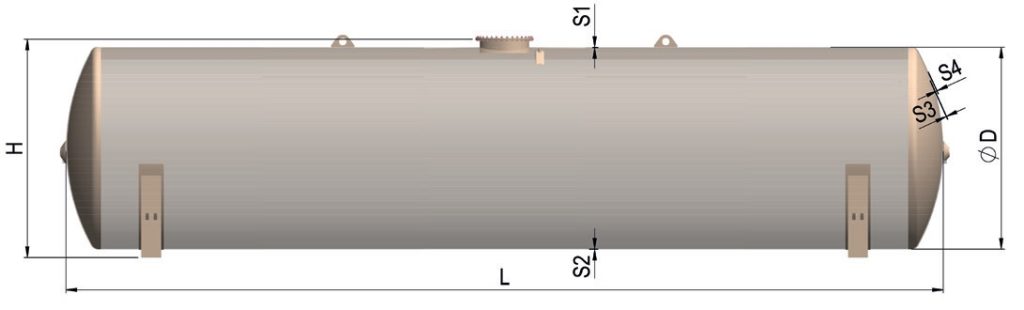

Aboveground tanks according to EN 12285-2 norm, Class A & B

| Volume | Diameter | Length | Height | Total weight | Additional

chamber weight |

Wall thickness | Dished-end thickness | ||||||||||

| class A | class B | class A | class B | class A | class B | class A | class B | ||||||||||

| V | D | L | H | Single skin | Double skin | Single skin | Double skin | S1 | S2 | S1 | S2 | S3 | S4 | S3 | S4 | ||

| [m3] | [mm] | [mm] | [mm] | [kg] | [kg] | [kg] | [kg] | [kg] | [kg] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] |

| 3 5 8 10 13 16 |

1600 1600 1600 1600 1600 1600 |

2080 3080 4580 5580 7080 8580 |

1870 1870 1870 1870 1870 1870 |

720 925 1233 1438 1745 2053 |

1036 1342 1800 2106 2564 3022 |

765 970 1278 1483 1790 2098 |

1082 1387 1846 2151 2609 3068 |

351 351 351 351 351 351 |

351 351 351 351 351 351 |

5 5 5 5 5 5 |

3 3 3 3 3 3 |

5 5 5 5 5 5 |

3 3 3 3 3 3 |

5 5 5 5 5 5 |

3 3 3 3 3 3 |

5 5 5 5 5 5 |

3 3 3 3 3 3 |

| 10 13 16 20 25 30 35 |

2000 2000 2000 2000 2000 2000 2000 |

3700 4700 5700 6700 8700 10200 11700 |

2270 2270 2270 2270 2270 2270 2270 |

1612 1918 2225 2532 3145 3656 4116 |

2235 2667 3100 3532 4397 5096 5745 |

1658 1964 2271 2577 3190 3702 4162 |

2281 2713 3146 3578 4442 5142 5791 |

522 522 522 522 522 522 |

522 522 522 522 522 522 |

6 6 6 6 6 6 |

3 3 3 3 3 3 |

6 6 6 6 6 6 |

3 3 3 3 3 3 |

6 6 6 6 6 6 |

3 3 3 3 3 3 |

6 6 6 6 6 6 |

3 3 3 3 3 3 |

| 20 25 30 40 50 60 70 |

2500 2500 2500 2500 2500 2500 2500 |

4840 5840 6840 8840 10840 12840 14840 |

2770 2770 2770 2770 2770 2770 2770 |

2591 2974 3358 4190 4956 5788 6574 |

4187 4832 5477 6832 8122 9477 10787 |

3055 3501 3947 4905 5797 6754 7666 |

4650 5358 6066 7547 8963 10444 11880 |

730 730 730 730 730 730 730 |

818 818 818 818 818 818 818 |

6 6 6 6 6 6 6 |

4 4 4 4 4 4 4 |

7 7 7 7 7 7 7 |

4 4 4 4 4 4 4 |

6 6 6 6 6 6 6 |

5 5 5 5 5 5 5 |

7 7 7 7 7 7 7 |

5 5 5 5 5 5 5 |

| 40 50 60 70 80 100 |

2900 2900 2900 2900 2900 2900 |

6950 8450 9950 11450 12950 15950 |

3170 3170 3170 3170 3170 3170 |

4579 5432 6208 7003 7856 9408 |

7124 8432 9664 10915 12223 14686 |

5965 7036 8031 9045 10117 12106 |

8510 10037 11487 12957 14484 17384 |

1045 1045 1045 1045 1045 1045 |

1279 1279 1279 1279 1279 1279 |

7 7 7 7 7 7 |

4 4 4 4 4 4 |

9 9 9 9 9 9 |

4 4 4 4 4 4 |

7 7 7 7 7 7 |

5 5 5 5 5 5 |

9 9 9 9 9 9 |

5 5 5 5 5 5 |

| 120 | 3000 | 18150 | 3270 | 11016 | 17127 | 14156 | 20267 | 1108 | 1357 | 7 | 4 | 9 | 4 | 7 | 5 | 9 | 5 |

*Other/larger volumes available on request

S1 – Inner wall

S2 – Outer wall

S3 – Inner dished-end

S4 – Outer dished-end

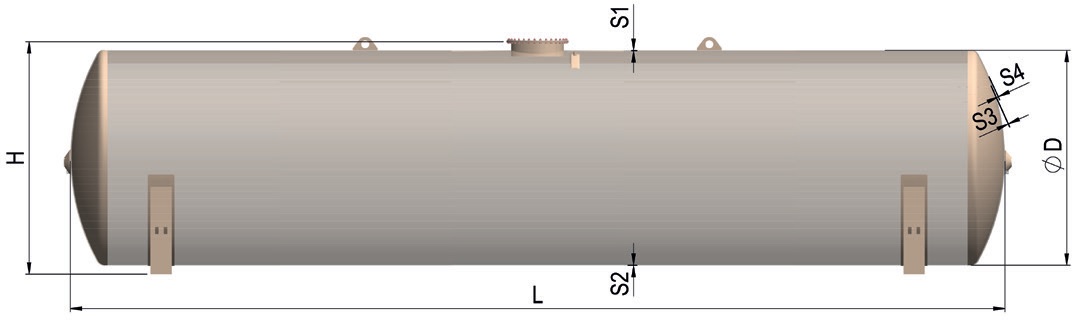

Aboveground tanks according to AD 2000 norm

| Volume | Diameter | Length | Height | Total weight | Additional

chamber weight |

Wall thickness | Dished-end thickness | |||

| V | D | L | H | Single skin | Double skin | S1 | S2 | S3 | S4 | |

| [m3] | [mm] | [mm] | [mm] | [kg] | [kg] | [kg] | [mm] | [mm] | [mm] | [mm] |

| 120 | 2900 | 18950 | 3240 | 14437 | 20627 | 1406 | 9 | 4 | 9 | 5 |

| 120 | 3000 | 18150 | 3340 | 14393 | 20504 | 1492 | 9 | 4 | 9 | 5 |

| 150 200 |

3200 3200 |

19750 26250 |

3540 3540 |

18259 23838 |

25328 30907 |

1671 1671 |

10 10 |

4 4 |

10 10 |

5 5 |

| 150 200 250 300 |

3400 3400 3400 3400 |

17790 23290 28790 34290 |

3740 3740 3740 3740 |

17844 22590 27336 32081 |

24694 31398 38102 44806 |

1862 1862 1862 1862 |

10 10 10 10 |

4 4 4 4 |

10 10 10 10 |

5 5 5 5 |

| 150 200 250 300 |

3600 3600 3600 3600 |

15870 20870 25870 30370 |

3940 3940 3940 3940 |

17048 21806 26374 30485 |

23601 30244 36697 42504 |

2064 2064 2064 2064 |

10 10 10 10 |

5 5 5 5 |

10 10 10 10 |

5 5 5 5 |

*Other/larger volumes available on request

S1 – Inner wall

S2 – Outer wall

S3 – Inner dished-end

S4 – Outer dished-end

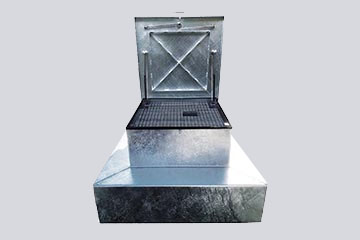

Tank Sumps

Steel tank sumps for green area

Street covers